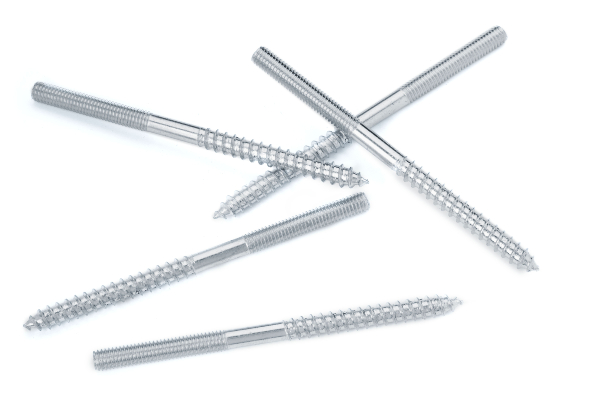

HV High strenght pre-load bolt assemblies

HV bolts for preloaded connections should be used according to EN 14399-4 for bolts and nuts, and EN 14399-6 for washers x 2 (with increased hardness of at least 300 HV).

The nuts are factory-coated with a lubricant containing molybdenum disulfide (MoS2), which reduces friction during tightening.

Bolts, nuts, and washers should come from the same manufacturer to ensure the repeatability of tightening parameters.

The sets are delivered in class K1.

For class K1, we select a combined tightening method consisting of two stages.

On the label, the contractor will find all the necessary information required for the proper assembly of the set.

Typical Applications:

- In steel constructions in preloaded butt joints

- In industrial construction in ordinary and friction lap joints

HV bolt sets for preloaded connections are used for assembling steel structures (as connecting elements in nodes, frame joints, at the supports of continuous beams, in the joints of girders and beams). HV sets are particularly recommended for use in structures subjected to seismic effects, dynamic loads, or fatigue. HV bolt sets should be used for lap connections: category B (in the serviceability limit state), category C (in the ultimate limit state) according to Eurocode 3, and in butt connections of category E. The rules for designing and executing bolted joints using HV sets are described in Eurocode 3 and EN 1090-2.

Advantages:

- Increased quality and durability of assembly joints

- Butt joints do not require special surface preparation

- No additional locking devices for the nuts are needed

- Hot-dip galvanized protective coating allowing use in C4 environments according to PN-EN 12944-1:6:2018

- Individual traceability based on marking

The requirements for HV bolt sets are defined by the harmonized standard EN 14399-1:5:2015.

Recommended

- Group

- 1133